SILICON AND RUBBER SELF LUBRICATION

Geschriben am 16-01-2012

ALL YOU HAVE TO KNOW ABOUT MATERIALS SELF-LUBRICATION

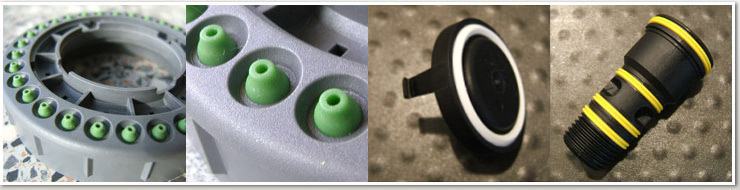

In order to facilitate mounting or assembling of rubber parts or electrical contacts, lubrication of parts in contact can be necessary.

Several difficulties can occur :

- chemical compatibility between lubricant and parts

- lubricant quantity and application

Self-lubricated materials can be more appropriate. This type of material will also have the advantage of preventing certain parts to stick together or onto another one also friction will decrease.

The product which will give to rubber a sliding effect is "non compatible" and incorporated during mixing operations in compound's mass.

Non compatibility of certain oils, soaps or waxes towards basical elastomers is used to get a "self-lubrication" property.

Quantity of these products can only be limited, as if incorporated in too large proportion, they just would not mix and would destroy compound's mechanical properties.

After vulcanisation, the mixed product will move from inside to part's surface, and will come out.

Self-lubricated parts finish varies according to age and is visible after some days or weeks.

More or less oily appearance does not depend exclusively from the % of oil content in the product. Compound type, hardness and structure will also make this appearance change.

Also initial % at compounding + temperature + time + atmosphere pressure influence this phenomena.

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES ET CAOUTCHOUCS ECO RESPONSABLES - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- 90, 95 und 10 Jahre Erfahrung für die Entwicklung Ihrer technischen ELASTOMER-Teile: Gummi; SILIKON; LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- EXTREME PERFORMANCES FOR RUBBERS & NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- RUBBER FRICTION

- RUBBER & SILICONE LSR THERMAL EXPANSION

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- http://de.wikipedia.org/wiki/Silicone

- http://en.wikipedia.org/wiki/Synthetic_rubber

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- SILICON AND RUBBER PARTS STORAGE

- SILICON AND RUBBER TEARING

- RUBBER PARTS ASSEMBLING AND MOUNTING

- YOUNG MODULUS FOR RUBBER

- RUBBER RESILIENCE

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER COMPRESSION SET

- RUBBER HARDNESS MEASUREMENT

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- CUSTOM LSR COLORS

- ELASTOMERS POST CURE

- SILICON AND RUBBER SELF LUBRICATION

- 7 th TECH DAYS

- 6èmes journées techniques