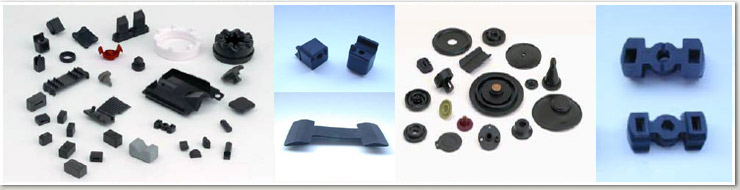

HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

Geschriben am 27-03-2013

"Composites" systems took a new place which “conventional systems” did not occupy for :

- integrating many functions into the same component (ex : case/seal)

- solving assembly problems (ex : diaphragm on micro part)

- function improvements (ex : no seal sliding on assembling)

In "1on2" communication ( INFORMATION LETTER N°57 CHEVALIER - CLERET - ELTEC ) we informed you about “traditional rubber adherisation” on support. In that present communication, we are going to explain you a different and innovative process allowing silicone rubbers polymers adherisation ( to stick ! ) on various supports.

Self bonding silicone LSR chemical sticking on support : Some LSR specific and quite new silicone grades allow to get support adherisation without adherisation agent treatment.

It is necessary to check compatibility and adherisation quality between support and self bonding LSR (support can be TP : PA - PBT - PPS; glass; metal...). Many characterization tests have already been realized: do not hesitate to reequest for us !

LSR reticulation is made around 180 °: cycle time depends from thickness, and is from 10 to seconds (usually); supports can not allow (due to heigt temperature deformation, flow…) these constraints are not so recommended.

SILICONE main characteristics reminder :

- working temperature good behaviour: - 50 °C until + 180 °

- good chemical resistances and good ageing (UV, colour…)

- much better mechanical performances than TPE : low hardness and modules, good various resistances

(compression set…)

- available food and medical-pharmaceutical grades : certifications Bfr, USP cl IV and FDA...

- “easy” process and "clean" / coloration is also easy even if limitated

- hardness from 10 to 70 shore A according to grades and very low modules associated with the lowest hardness

- self lubrification grades availability: "non compatible silicone oil" is present inside material and is "bleeding" in time=> this avoids seal lubrication and is easy for assembly

Please do not hesitate to contact jm.oudot@chevalier-cleret.fr for getting full content of our INFORMATION LETTER Nr 59 ( this above intricution is part or our Nr 59 technical letter ) already published.

Also we could provide to you several technical supports AND all links to YOU TUBE on line process videos for getting 'images' !

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES ET CAOUTCHOUCS ECO RESPONSABLES - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- 90, 95 und 10 Jahre Erfahrung für die Entwicklung Ihrer technischen ELASTOMER-Teile: Gummi; SILIKON; LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- EXTREME PERFORMANCES FOR RUBBERS & NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- RUBBER FRICTION

- RUBBER & SILICONE LSR THERMAL EXPANSION

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- http://de.wikipedia.org/wiki/Silicone

- http://en.wikipedia.org/wiki/Synthetic_rubber

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- SILICON AND RUBBER PARTS STORAGE

- SILICON AND RUBBER TEARING

- RUBBER PARTS ASSEMBLING AND MOUNTING

- YOUNG MODULUS FOR RUBBER

- RUBBER RESILIENCE

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER COMPRESSION SET

- RUBBER HARDNESS MEASUREMENT

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- CUSTOM LSR COLORS

- ELASTOMERS POST CURE

- SILICON AND RUBBER SELF LUBRICATION

- 7 th TECH DAYS

- 6èmes journées techniques