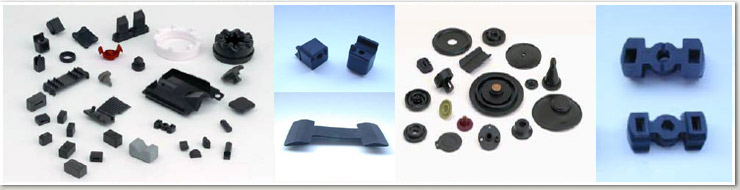

SILICON AND RUBBER PARTS STORAGE

Geschriben am 05-02-2013

ALL YOU HAVE TO KNOW ABOUT ELASTOMERS PARTS STORAGE

NF 47507 norm recommendation:

"Packings must be light proof and stocked in a fresh, dry, and not dusty area."

Temperature

Temperature to be between +5° C and +35° C.

Physical properties modifications can occur mainly due to higher temperatures (above 30° C). Beware of heat sources close to the stocking area !

Low temperatures are not likely to interfere rubber parts quality. But a few elastomers can become very stiff with low temperatures (- 40° C and beyond). They must be brought back to normal temperatures during a few hours before being used or mounted.

Humidity

best humidity value is between 45 and 70 %.

Light

Elastomer parts must be protected from light : sun beams, artificial lights rich with UV or ozone (fluorescent light tubes).

Cardboard or plastic boxes are recommended.

Oxygen and ozone

Stocking conditions must prevent elastomer parts against fresh air. Stocking area must not be close to an equipment producing ozone, or fluorescent tubes, mercure lights, electric motors or equipment producing sparks.

Thinners, petrol, chemical producs, acids must not be stores in the same area.

Deformation

Make sure not to store elastomer parts in non rigid packings or boxes.

Parts deformation could prevent a correct use and mounting, or lead to bad function.

Stocking duration

There is no norm related to this question.

According to matelials, following evaluation is possible:

3 years for NR, SBR

8 years for NBR, CR, AU/EU, NBR/PVC…

15 years for silicone EPDM, FPM, FMVQ, HNBR, VMQ, LSR, AEM, ACM…

Maximum stocking in the best conditions mentioned here above

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES ET CAOUTCHOUCS ECO RESPONSABLES - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- 90, 95 und 10 Jahre Erfahrung für die Entwicklung Ihrer technischen ELASTOMER-Teile: Gummi; SILIKON; LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- EXTREME PERFORMANCES FOR RUBBERS & NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- RUBBER FRICTION

- RUBBER & SILICONE LSR THERMAL EXPANSION

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- http://de.wikipedia.org/wiki/Silicone

- http://en.wikipedia.org/wiki/Synthetic_rubber

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- SILICON AND RUBBER PARTS STORAGE

- SILICON AND RUBBER TEARING

- RUBBER PARTS ASSEMBLING AND MOUNTING

- YOUNG MODULUS FOR RUBBER

- RUBBER RESILIENCE

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER COMPRESSION SET

- RUBBER HARDNESS MEASUREMENT

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- CUSTOM LSR COLORS

- ELASTOMERS POST CURE

- SILICON AND RUBBER SELF LUBRICATION

- 7 th TECH DAYS

- 6èmes journées techniques