RUBBER RESILIENCE

Geschriben am 29-01-2013

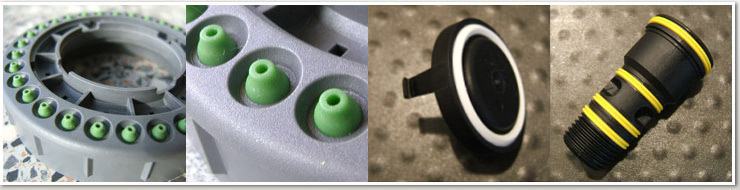

The great majority of the rubber parts is intended for dynamic applications; it is in particular the case of the bellows of transmission, engines’supports and elastic articulations. This is why all of these parts must be rigorously controlled, which required the development and the standardization of many testing methods.

Concerning the resilience of an unspecified material (and thus of a vulcanized rubber), it should be known that this parameter represents the link between the energy restored by this material after being deformated and the energy which had been provided to ensure this deformation .

This parameter will be fundamental since it will represent the aptitude of a material to absorb a shock

what is crucial for different parts produced by our company. The ductility of a material can be obtained

by various ways

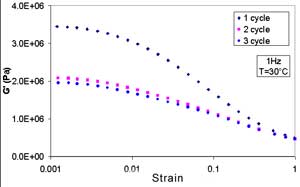

• From the hysteresis loops obtained by successive tractions and relaxations of a sample using a dynamometer. Let us keep in mind that at the time of this test, it is necessary to wait some cycles to be freed from MULLINS’ effect.

• It is also possible to determine the ductility by subjecting a sample (generally spherical shaped and of a few millimetres thickness) to a shock thanks to a system of beam. The height reached by the arm after rebounding directly gives the resilience of bounce of the material (Standard NF T 46 012). One of the apparatuses mostly used for this determination is the LUPKE reboundimeter.

• Lastly, the RPA 2000 (Rubber Process Analyzer), present within our laboratory, enables us to carry out tests of post-cure giving us access with the viscoelastic properties such as the resilience of the compounds cured in the testing chamber. Then, various tests were developed such as frequency sweeps, deformation sweeps and simulations of tests called strain/relaxation, whose operational limits are directly linked to the use of the finished products.

- NEWS N°184, Production of bipolar plates for fuel cells using the LSR injection process, type 3025-40 or EPDM, FKM, ...

- NEWS N° 182 - The CHEVALIER - CLERET - ELTEC Group in summury

- CHEVALIER CLERET ELTEC SILICONES ET CAOUTCHOUCS ECO RESPONSABLES - French Business Climate Pledge 11/12/2017

- FLUORINATED ELASTOMER FKM FPM RUBBER FOR PHARMACEUTICAL USES & FOOD CONTACT APPLICATIONS ALSO STERILIZABLE

- 90, 95 und 10 Jahre Erfahrung für die Entwicklung Ihrer technischen ELASTOMER-Teile: Gummi; SILIKON; LSR

- SELF LUBRICATED NITRILE NBR COMPOUND

- NITRILE NBR FOR GAZ APPLICATIONS NF EN 549

- EXTREME PERFORMANCES FOR RUBBERS & NEW OPPORTUNITIES THROUGH FLS FFLS FLUORO LIQUID SILICONE NEW GRADES AVAILIBITY

- HOW TO GET MOULDED RUBBER PARTS & THERMOPLASTIC TP + SELF BONDING LSR CO INJECTION

- RUBBER PARTS INSPECTION & "IN PRODUCTION" FUNCTIONNEL TESTS

- RUBBER FRICTION

- RUBBER & SILICONE LSR THERMAL EXPANSION

- HYBRIDS : RUBBER BONDING ON METAL (1on2) also named "rubber metal"

- HYBRIDS : LIQUID SILICON RUBBER LSR SELF BONDING ON TP - THERMOPLASTIC (2on2) also named "self bonding lsr silicone"

- http://de.wikipedia.org/wiki/Silicone

- http://en.wikipedia.org/wiki/Synthetic_rubber

- RUBBER REUSE ( HIGH TEMPERATURE VULCANIZATION / CURE ELASTOMERS; SILICONES & LIQUID SILICONE RUBBERS / LSR)

- SILICON AND RUBBER PARTS STORAGE

- SILICON AND RUBBER TEARING

- RUBBER PARTS ASSEMBLING AND MOUNTING

- YOUNG MODULUS FOR RUBBER

- RUBBER RESILIENCE

- RUBBER TANGENT DELTA (TAN DELTA)

- RUBBER TENSILE STRENGTH AND ELONGATION AT BREAK

- RUBBER COMPRESSION SET

- RUBBER HARDNESS MEASUREMENT

- TO BE SEEN IN PHARMAPACK 2012 - Paris

- CUSTOM LSR COLORS

- ELASTOMERS POST CURE

- SILICON AND RUBBER SELF LUBRICATION

- 7 th TECH DAYS

- 6èmes journées techniques